News

25

2022

-

04

Jiuwu High-tech Complete Water Treatment Solution Helps "Carbon Peak, Carbon Neutral"

Author:

Source:

Huicong Water Industry Network, April 22-In March, when the spring breeze is mighty, the two sessions sounded a new horn and started a new journey. "Carbon peak", "carbon neutral" once again become a hot topic. After 2021, "double carbon" was once again written into the government work report, proposing to "orderly promote the carbon peak carbon neutralization work and implement the carbon peak action plan". China is the world's largest energy consumer. Under the background of "double carbon", the energy problem has become an increasingly prominent development problem in China, and the development of clean and environmentally friendly renewable energy has attracted more and more attention. At present, fuel ethanol is accepted and studied by more and more countries as a clean and renewable energy source on a global scale. According to statistics, every production of l t ethanol will produce 20 t wastewater. Fuel ethanol wastewater is organic wastewater with high concentration, high temperature and high suspended solids, and the wastewater contains a large amount of volatile acids with pH of 4~5. Direct discharge of these wastewater will cause serious environmental pollution, and the wastewater problem has become a common problem restricting the sustainable development of fuel ethanol industry. How to treat fuel ethanol wastewater economically and efficiently has always been one of the important research topics of common concern to scientific research institutions and enterprises.

Through years of research and transformation, a New Energy Technology Co., Ltd. successfully used CO from industrial production tail gas such as iron and steel smelting as carbon source, ammonia as nitrogen source, and added nutrient salts for biological fermentation to prepare fuel ethanol and by-product ethanol Clostridium protein feed. In the production process, will produce all kinds of process wastewater, wastewater with high COD, high total nitrogen, high total phosphorus, high volatile acid and other characteristics, belongs to the difficult industrial wastewater.

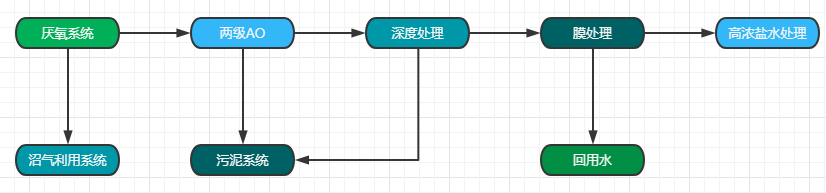

Jiuwu Gaoke for biological fermentation ethanol wastewater treatment, the use of anaerobic digestion two-stage AO biochemical method double membrane system process, the process has the characteristics of impact load, low investment, stable operation, low energy consumption and energy recovery. First, anaerobic digestion is used to treat high-concentration wastewater to degrade most of the organic matter in the wastewater and produce biogas. Anaerobic reactors and biogas treatment facilities are closed systems and will not be emitted into the surrounding environment. Biogas has considerable economic value and can be supplied to boilers. Two-stage aerobic-facultative oxygen is used to further remove most of the organic matter in the biogas slurry and remove ammonia and phosphorus. After biochemical treatment, most of the easily biochemical substances in wastewater have been decomposed by microorganisms. For COD that cannot be removed by biological and coagulation systems, advanced oxidation methods are needed to remove it to meet the requirements of ultrafiltration and reverse osmosis membranes, and achieve zero emission or near zero emission after membrane concentration.

The main process flow is as follows